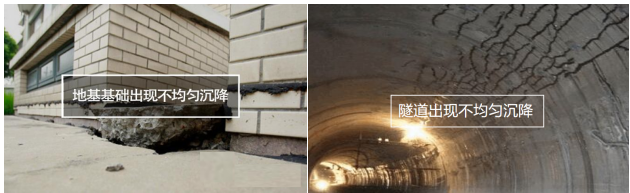

Monitoring Background:

Vertical deformation or settlement of the ground surface due to load-bearing by structures (buildings, tunnels, embankments) is inevitable. Uniform settlement has less impact on structures, but attention must also be paid to the rate of settlement. The key concern is that uneven settlement can cause serious harm to structures, leading to additional stress, cracks in the structure, and fractures in local components, thereby endangering the safety of the structure. Therefore, using a static level instrument to monitor the settlement of key parts of structures plays a very important role.

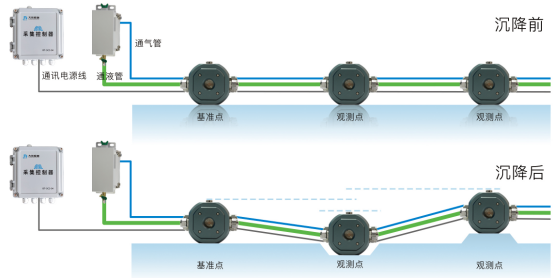

Monitoring Principle:

The settlement monitoring system of the differential pressure static level instrument is composed of multiple static level instruments, liquid reservoirs, data collectors, and interconnecting pipes. Within the structural monitoring area, according to the design requirements, the static level instruments are installed at various observation points. A stable structural area is selected nearby to set the benchmark point and install the static level instrument and liquid reservoir. All observation points, benchmark point instruments, and liquid reservoirs are interconnected with liquid pipes and air pipes. When the observation point undergoes vertical displacement, the pressure difference between that observation point and the benchmark point will change accordingly. By converting and calculating, the vertical displacement of the point can be determined.

Technical Specifications:

Model | DT-HLS-100 | DT-HLS-300 | DT-HLS-500 |

Range | 0-1500mm | 0-3000mm | 0-5000mm |

Note: The range refers to the height difference relative to the liquid level in the reservoir, with the height of a water column as the reference. | |||

Accuracy | ≤0.03%FS | ||

Resolution | 0.01mm | ||

Operating Voltage | 7-17V | ||

Liquid Pipe Specifications | 10*6.5mm | ||

Waterproof Performance | P68(When the air tube and liquid tube are blocked) | ||

Pressure Medium | Water, antifreeze, silicone oil; antifreeze is recommended. | ||

Communication Interface | RS485 | ||

Air Tube Specifications | 8*5mm | ||

Operating Temperature | -25°℃-85℃ | ||

Technical Advantages and Disadvantages:

Advantages: Low cost, large range, high precision, and high sampling frequency.

Disadvantages: Affected by temperature differences and vibrations at the installation site, such as large day-night temperature variations or significant vibrations during the data collection process, the data from the differential pressure static level instrument can vary greatly.

Layout Plan:

Conduct vertical settlement intelligent monitoring on the monitored section of the road, and install a settlement sensor at intervals of 5m-20m according to the actual situation on site.

Monitoring Frequency:

The intelligent monitoring system can remotely set the monitoring frequency parameters through the data platform. Under normal circumstances, the sampling frequency is fixed and remotely adjustable. If the system detects abnormal changes in the measured data, it adaptively adjusts to increase the sampling frequency. Later, the observation time is determined based on the settlement and planar settlement deformation of the deformation monitoring points and the requirements of various professionals.

Monitoring Results:

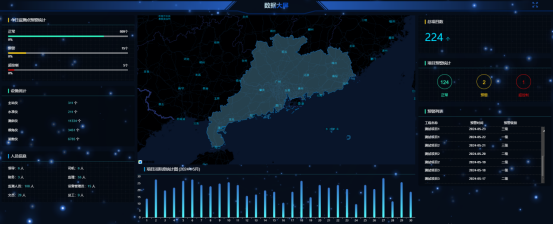

The following monitoring results can be obtained through the automated monitoring system:

(1) It can automatically collect data, and staff can monitor remotely by logging into the data platform to obtain real-time deformation values, deformation rates, and time-history curves. Real-time exceedance warnings can be issued by setting threshold values.

(2) Real-time monitoring of the settlement data for individual points at the current time, and comparative analysis of the changes in the monitoring data from the most recent two periods. It allows for real-time comparative analysis of settlement monitoring data across various cross and longitudinal sections, and the ability to add monitoring data from multiple periods at different times to grasp the developmental patterns of the monitoring points over time.

(3) Monitoring data is stored and displayed in real-time, and supports data export for later analysis.

(4) Through the automatic monitoring system, real-time monitoring and early warning of deformation data are achieved, enabling real-time control over the allowable deviation management values of buildings, tunnels, and roadbed deformations, ensuring operational safety.

Static Level Instrument System Architecture Diagram

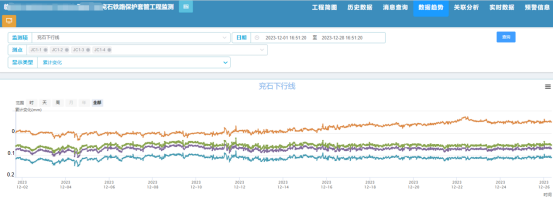

Monitoring Dashboard

Static Level Instrument Monitoring Data Curve Diagram