How can power pipeline measurement and positioning be carried out efficiently and accurately in complex natural environments and under stringent engineering requirements? Today, we will share a successful case from Tawau, East Malaysia, and see how Kum Fatt Engineering Sdn Bhd overcame these challenges using advanced technological equipment.

Project Background: Measurement Challenges in a Complex Environment

In Tawau, East Malaysia, a non-excavation power pipeline spanning over 30 kilometers required inertial measurement and positioning. The pipeline, with a diameter of 160mm and made of PVC, was primarily used for power transmission. However, the project team faced numerous challenges: the pipeline was located at the edge of a jungle, surrounded by dense weeds. Moreover, from September to October, the rainy season caused frequent rainfall, leading to the accumulation of mud and weeds inside the pipeline, which posed significant difficulties for the measurement work.

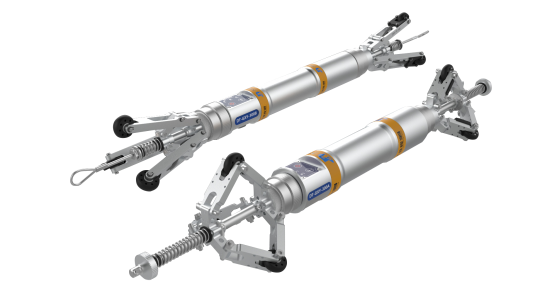

To ensure the smooth progress of the measurement, Kum Fatt Engineering Sdn Bhd chose the DT-GXY-300C series pipeline inertial measurement instrument from Datie Inspection. Before measurement, each pipeline was thoroughly cleaned to eliminate interference from foreign objects inside the pipe. Despite potential issues during the measurement process, such as small stones, wheel groups getting muddy, and large weld seams, the equipment from Datie Inspection was still able to ensure the accuracy of the data.

Measurement Technology and Equipment: The Key to Accurate Measurement

Introduction to Inertial Measurement Technology

Inertial measurement technology is an advanced technique that uses inertial sensors to measure the motion state of an object. By calculating parameters such as acceleration and angular velocity, it can determine the position, velocity, and attitude of the object. In pipeline measurement, this technology can accurately measure the internal structure of the pipeline, providing crucial data support for construction, maintenance, and emergency repairs.

Data Processing and Precision Control

The DT-GXY-300C series pipeline inertial measurement instrument from Datie Inspection performed exceptionally during the measurement process. It can collect data in real-time and correct and optimize it through advanced data processing algorithms to ensure high precision. The equipment also has an automatic compensation function that can effectively eliminate errors that may occur during measurement, such as small stones being dragged out, wheel groups getting muddy, and large weld seams, thereby ensuring that the data quality remains within the precision range required by the client.

Technical Advantages and Application Prospects

Inertial measurement technology has significant advantages, including high measurement accuracy, fast speed, and being unaffected by the environment. It is particularly suitable for pipeline measurement in complex environments. In industries such as power, gas, oil, heat, and communications, this technology has demonstrated great application value and broad development prospects in scenarios like pipeline census, detailed investigation before construction, final acceptance, and emergency repairs.

Measurement Process and Results: Efficient Task Completion

Measurement Process

Before measurement, the project team cleaned each pipeline to ensure no foreign objects were inside and checked the performance and condition of the equipment to ensure it functioned properly. During the measurement process, the team strictly followed operating procedures, recording measurement data and equipment status in a timely manner. When issues such as small stones being dragged out, wheel groups getting muddy, and large weld seams occurred, team members quickly took measures to address them, ensuring the smooth progress of the measurement work.

Measurement Results

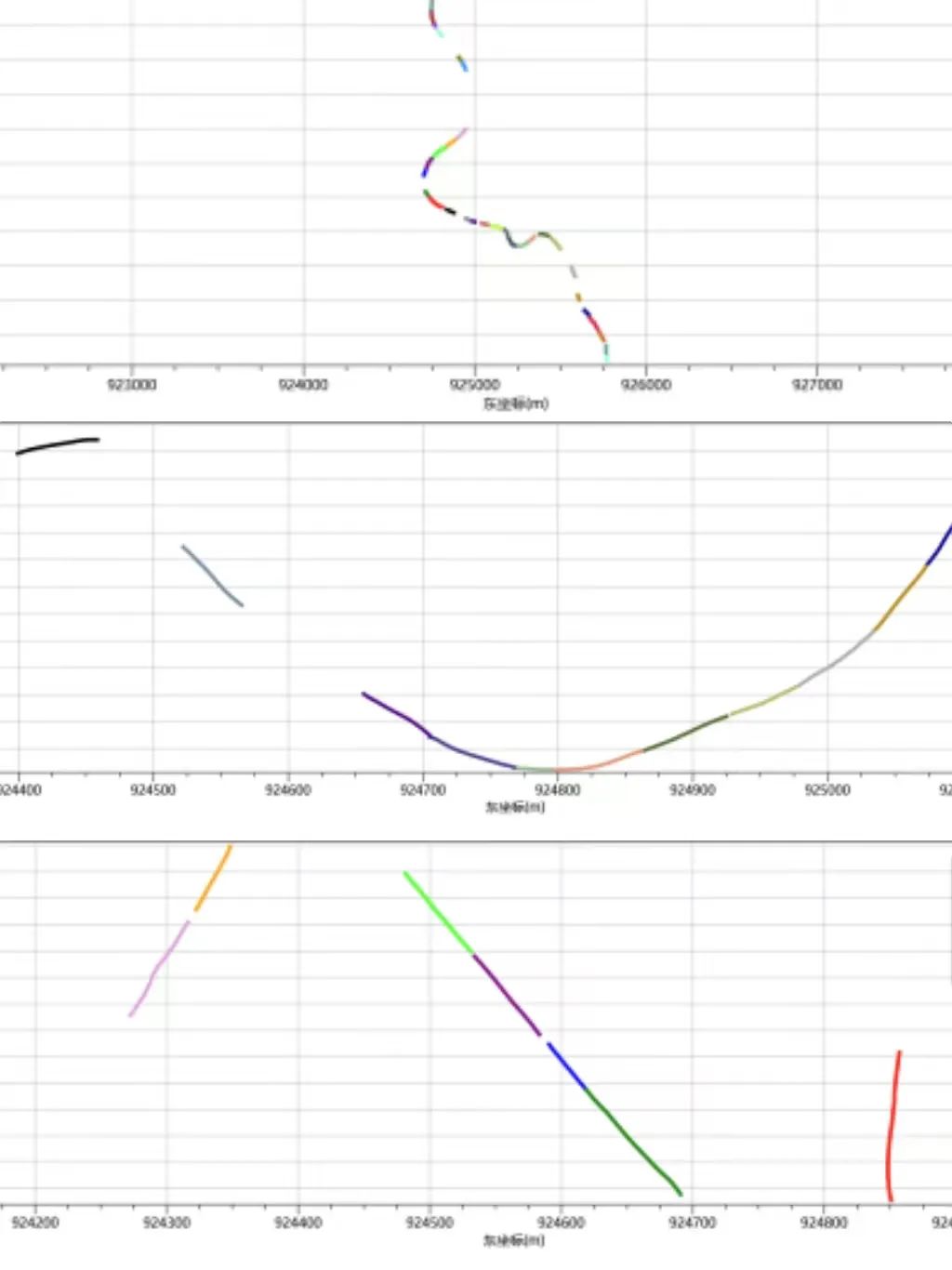

After the measurement was completed, the team processed and analyzed the collected data, extracted useful information, and visualized the data according to client requirements, generating an intuitive 3D pipeline model and measurement report that were easy for clients to understand and use.

The DT-GXY-300C series pipeline inertial measurement instrument from Datie Inspection performed well during the measurement process, maintaining data quality within the precision range required by the client. The results showed that the equipment could maintain high measurement accuracy even in complex environments, meeting the needs of various application scenarios such as pipeline census, detailed investigation before construction, final acceptance, and emergency repairs in power, gas, oil, heat, and communications industries.

The precise and reliable data provided important references for the client's pipeline construction, maintenance, and emergency repairs, effectively ensuring the safe operation of the pipeline. The measurement results can also be used for pipeline digital management, providing data support for long-term pipeline maintenance and management. The client validated and provided feedback on the measurement results, considering the DT-GXY-300C series pipeline inertial measurement instrument from Datie Inspection to be accurate and reliable, meeting their engineering needs. The successful application of this equipment has provided a reliable solution for the pipeline measurement industry and received high recognition from the client.

Project Summary: Overcoming Challenges Successfully

The inertial measurement and positioning project for the power pipeline in Tawau, East Malaysia, was successfully completed in a complex environment with precise and reliable results. The project team overcame adverse factors such as the rainy season and dense weeds, successfully completing the inertial measurement of over 30 kilometers of non-excavation power pipeline. This achievement not only provided important data support for the client's pipeline construction and maintenance but also offered valuable experience for the implementation of similar projects.

In future projects, with continuous technological innovation and expanding applications, we believe that inertial measurement technology will play an even greater role in more fields, providing more efficient and accurate solutions for infrastructure construction and maintenance.